What is Prepress?

Posted by Clash Printing Atlanta on 17th Apr 2024

What is prepress? It’s the unsung hero of the printing world, ensuring your digital designs are perfectly primed for print. This critical step transforms creative files into a print-ready format, ironing out any potential snags in image resolution, color fidelity, and layout that can affect the outcome. Let’s delve into how prepress makes all the difference before printing a single page.

Key Takeaways

The prepress process is a critical stage in printing, during which digital files are prepared and optimized through rigorous checks, including proofreading, resolution adjustments, and color accuracy, to ensure they meet the printer’s specifications and are ready for printing.

Proofs are a vital part of the prepress process, serving as a preview to catch potential issues and ensure the final printed product will look as expected, with detailed attention given to color separations and layout, offering options between soft proofs for quick review or physical proofs for a more tactile experience.

Digital prepress technology has streamlined the prepress workflow, with advancements in automation and tools like CTP systems improving productivity and precision. Customizing this process is crucial to cater to different print projects and printing methods, such as digital versus offset printing.

Decoding the Prepress Process

The prepress process, also known as prepress, plays a pivotal role in the printing industry. It is a complex interplay of technology and expertise. Prepress acts as the bridge between creative conception and the physical act of printing, ensuring that the digital files are primed for a successful print run.

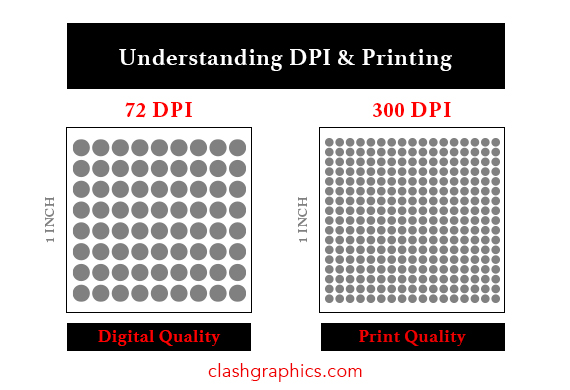

The journey begins with the pre-flight stage, a crucial checkpoint where the artwork is subjected to rigorous validation. From resolution checks to color setups and layout element inclusion, every detail is scrutinized to align with the printer’s requirements. This meticulous optimization, including proofreading, image resolution adjustments, and color accuracy checks, is not merely a formality; it’s the foundation for excellence in printed materials.

Understanding File Preparation

File preparation, requiring meticulous attention to detail and strict adherence to a prepress checklist, forms the bedrock of the prepress workflow. A graphic designer engages in a strategic dance with pixels and vectors, sizing and cropping images, flattening layers, and conducting spell checks to ensure the graphics file is ready to transition from conception to print-ready form.

This dance continues as designers merge drop shadows, convert text blocks to outlines, and create the necessary crop marks that guide the final cut. This ensures that the file stands up to the scrutiny of the printing press and emerges as the envisioned final printed product.

The Importance of Color Management

Color management in graphic design can be likened to conducting a symphony, wherein each hue must strike the perfect note. Artificial intelligence lends a hand here, automating color management to ensure print consistency, batch after batch, a testament to the evolution of digital printing. The pantone system is a great tool for color matching, but not every printer offers or uses it. The color management process involves detailed steps like transparency flattening and color separation; each meticulously performed to create a color-accurate proof that accurately represents the final product.

When it comes to offset press printing, customization entails:

preparing separate plates for each CMYK color

using pre-mixed Pantone inks for precise color matching

ensuring that the final print project reflects the original vision with stunning accuracy.

The Proofing Phase: Ensuring Client Satisfaction

Within the prepress workflow, the proofing phase serves as the guardian of quality and the predictor of client satisfaction. It is a critical juncture where the printing company and the client align their expectations, scrutinizing every detail to ensure mutual agreement on the anticipated outcome.

Proofs serve as the crystal ball of printing, offering a glimpse into the future by validating the appearance and placement of design elements before the printing press roars to life. This phase catches any lurking issues, ensuring that color separations, overprinting, and necessary elements are all in complete agreement and ready for the final print.

Soft Proofs vs. Physical Proofs

The contention between soft and physical proofs essentially boils down to convenience versus tangibility. Soft proofs, often in PDF format, offer a swift and cost-effective solution, allowing for a rapid review on computer screens and equally rapid electronic approval.

In contrast, physical proofs provide a tactile experience, allowing for hands-on examination of paper thickness, texture, and layout—a close representation of the final product that is especially crucial for projects with unique finishing operations like binding or special textures.

The Role of Printing Plates in Commercial Printing

The printing plate is a crucial component required for transitioning from digital files to the tangible sphere of commercial printing. In the time-honored offset printing process, these plates are the conduits through which the final design is transferred onto paper, a crucial step in the printing process.

Each color of the CMYK spectrum demands its own set of plates that are installed with precision into the printing press. Their durability and flexibility are tested against the rigors of thousands of impressions to ensure the successful print run of the final print project.

From Digital to Physical: The Plate-Making Process

Transforming digital art into physical printing plates involves a photomechanical process, wherein a photosensitive layer is exposed to light, imprinting the design onto the plate’s surface. The modern twist in this age-old process comes from Computer-To-Plate (CTP) technology, where laser engraving redefines precision by directly inscribing the design onto thermal plates.

Once the laser has done its work, a cleaning solution reveals the inked image, preparing the plate for its role in the press and paving the way for the final printed product.

Preparing for the Press: Final Steps Before Printing

As the prepress stage approaches its culmination, a series of final checks and balances become the focal point. Here, physical proofs are meticulously examined, not just for their visual appeal but for the tactile sensations they convey—the weight and texture of the paper that will carry the final printed product into the world.

Special projects, with their unique demands for finishing operations, hinge on the accuracy of these proofs, making them indispensable for ensuring that the final product aligns perfectly with client expectations.

Final Checks and Balancing

The last mile of the prepress process is a testament to the attention to detail that defines the craft. Linguistic and graphic proofreading are the final guardians against errors, ensuring that text and visual elements are not just correct but resonate with the intended audience. At this stage, a trained prepress technician becomes the maestro, orchestrating the correct color modes and overseeing the final prepress checks.

Their expertise ensures the file is print-ready and that the final print project, with its well-crafted print layout, will emerge from the press as a true reflection of the designer’s intent.

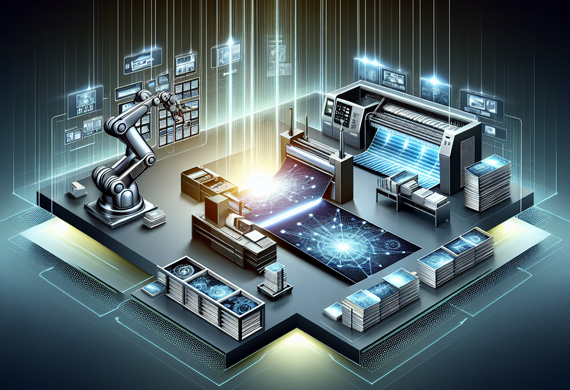

Digital Prepress Technology: Streamlining the Workflow

Digital prepress technology has significantly transformed the landscape of the printing industry. What once involved laborious manual steps and endless back-and-forth is now a streamlined, efficient process, thanks to digital prepress technology.

Innovations like the PlateRite series have transformed the prepress department of yesteryear. Their reliability has revolutionized the market and become a byword for precision in plate creation.

Advancements in Digital Automation

Digital automation has swept through the prepress process, bringing a surge in productivity and reduced errors. Technologies like EXILE’s thermal imagesetters and direct-to-screen systems exemplify cutting-edge advancements in reshaping prepress workflows.

Screen’s Equios solution, a beacon of automation, streamlines production steps, while cloud-based tools usher in a new era of collaboration, enabling remote teams to work in tandem on projects, enhancing both workflow and communication.

Tailoring Prepress for Different Print Projects

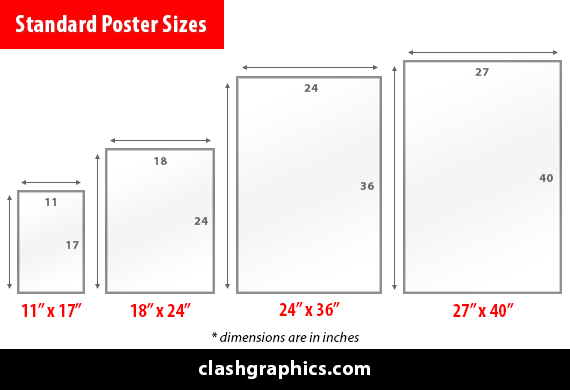

The prepress stage does not adhere to a one-size-fits-all approach. Different print projects, from the compact real estate of a business card to the sprawling canvas of a brochure, demand a tailored approach to ensure each print project meets its unique needs. Even within the seemingly narrow confines of a business card, a spectrum of creative possibilities exists, such as four-panel folded cards that double as miniature brochures, each requiring their own prepress customizations during the pre-press stage.

Customization According to Printing Method

The approach to prepress customization varies significantly between digital presses and offset printing. Digital presses offer a kaleidoscope of color options, making them ideal for small print runs and personalized projects.

Offset printing, conversely, is the workhorse of high-volume print jobs, where its initial setup costs are offset by its cost-effectiveness over large runs.

Insights from Industry Experts

As we enter a new era in the printing industry, experts highlight emerging trends such as artificial intelligence and cloud-based collaboration as catalysts of a revolution in prepress processes. These innovations promise to usher in an era of unprecedented efficiency and precision, minimizing costly mistakes and propelling the industry toward a future where imagination is the only limit.

The Prepress Summary

From the nuanced art of file preparation to the precision of plate making and the transformative impact of digital automation, the prepress process is a testament to the meticulous attention to detail that underpins the printing industry. As we’ve journeyed through the stages that ensure the translation of digital designs into stunning printed materials, it’s clear that prepress is the unsung hero of print production. The next time you hold a printed piece in your hands, remember the intricate ballet that made it possible and revel in the knowledge that the printed page is not just a product but a crafted masterpiece.

Prepress Frequently Asked Questions

These are the prepress questions frequently asked of our Atlanta printing team.

What is graphic prepress?

Graphic prepress is the process of preparing artwork for press, including media selection, proofing, quality control checks, and, if necessary, creating printing plates. It often involves working with print-ready PDF files provided by the customer.

What is the difference between prepress and pre-flight?

The main difference between prepress and pre-flight is that prepress involves setting up the design according to printer specifications. In contrast, pre-flight is the final check to ensure error-free files are ready for printing. Therefore, prepress focuses on design setup, while pre-flight ensures file readiness for printing.

What is the pre-flight stage in the prepress process?

The pre-flight stage in the prepress process involves validating artwork for resolution, color setup, and layout elements to ensure it meets printing standards.

How does color management affect the final printed product?

Color management is crucial for ensuring that the colors in the digital design are accurately reproduced in the final print, involving calibration, setting up color profiles, and detailed processes like color separation and trapping. It directly impacts the accuracy and quality of the printed material.

What is the difference between soft proofs and physical proofs?

The main difference between soft and physical proofs is that soft proofs are digital files viewed on a screen for quick review. In contrast, physical proofs are tangible samples that provide a more accurate representation of the final product. Digital proofs are cost-effective, while physical proofs allow evaluation of texture and layout.

(678) 235-3464