You may also send the file in the following types: pdf, jpg, jpeg, psd, tif, tiff, eps, ai, and png

We prefer that you send .PDF and .EPS files with outlined fonts. These files are easier to handle and will likely speed up your turn-around. Remember to add crop marks and flatten your files before uploading.

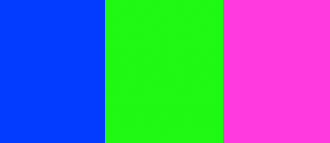

If you send us an RGB file, there is a chance that a color shift may occur and you may not be satisfied with your job.

THESE COLORS ARE IN RGB

THESE ARE THE SAME COLORS BUT IN CMYK

You should always start and finish your designs in CMYK color mode.

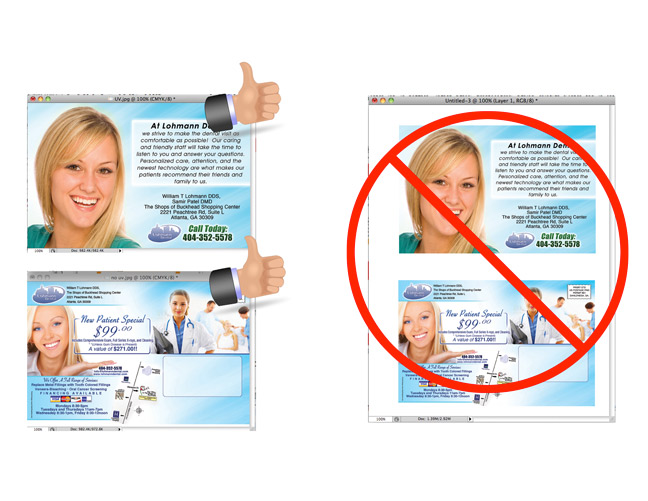

Low resolution files may be printed as is or will be placed on hold until we receive new files, slowing your turn-around.

THESE ARE 72 DPI LOW RES IMAGES

THESE ARE THE SAME IMAGES BUT AT 300 DPI

We only accept 300 dpi files and no less.

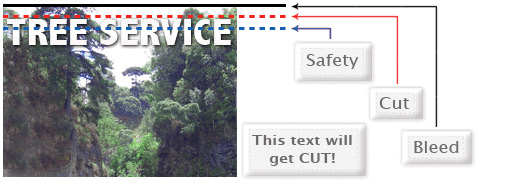

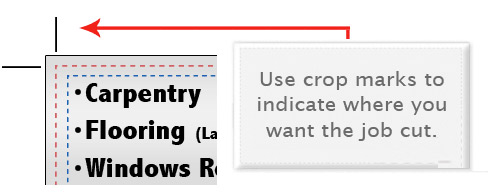

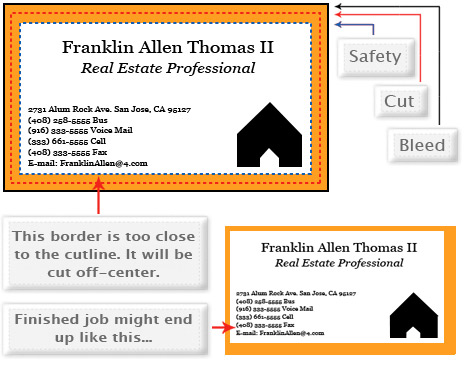

Bleed must extend further than the cut line. Using one of our Templates can help you visulize this. Please keep all text and anything you do not want to get cut off at least .125" away from the cut lines.

When sending an .eps or .pdf, make sure you include crop marks so we can cut the job correctly.

Click here to go to our production templates.

Yes but if the border is too close to the cutline, it may be off-center slightly.

We cut through many sheets at one time, so watch your borders to avoid an unwanted mistake.

No. Each side of the job needs to be on a seperate file.

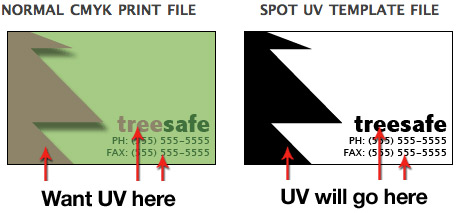

When creating a Spot UV Job, you must include a Spot UV template file along with the regular full color file. The Spot UV fileis used to show where the UV will be placed.

Use 100% K to indicate where you would like the UV. White will indicate no UV.

Silver ink files must be sent in a vector format. You must use a vector program, like Illustrator or Indesign, to call out the object you want in silver ink.

To indicate the silver ink, you must set the object color to Pantone¨ 877 C. Any other color will not be accepted as silver. Also, labeling the layer as "silver mask" or "silver" will not qualify your file.

VECTOR BASED PROGRAMS RASTER PROGRAMS

When using a blue in your design, always make sure to leave at least a 30% difference in your Cyan and Magenta values.

100% C 100% M 0% Y 0% K

ON SCREEN

AFTER PRINTING

Blue is close to purple in the CMYK spectrum. Remember, use a low amount of magenta whenever using high amounts of cyan to avoid purple.

EXAMPLE: C-100 M-70 Y-0 K-0

When exporting from any program such as Indesign or Illustrator, use these settings to make sure your .PDF files export correctly.

EXPORT SETTINGS FOR .PDF FILES

Adobe PDF Preset is set to: Press Quality

![]()

Compatibility is set to: Acrobat 4 (PDF 1.3)

![]()

Compress Text and Line Art is set to: Off

![]()

Grayscale images that are converted to CMYK will have a color shift in the final print. That shift may be green or yellow.

GRAYSCALE ON SCREEN

GRAYSCALE AFTER PRINT

Always check the CMYK values of your grayscale in the final CMYK document. If there are other values other than K in your grayscale image, there is a chance that the color will vary.

To eliminate all values other than K, use your Channel Mixer (adjustment layer) in Photoshop, then click "Monochrome" and adjust accordingly.

Rich black is an ink mixture of solid black, 100% K, with additional CMY ink values. This results in a darker tone than black ink alone. If you print black alone as 100% K, the resulting black may not be as dark as you might like.

100% K ON SCREEN

100% K AFTER PRINT

We recommend using C 60 M 40 Y 40 K 100

This will give you a deep, dark, rich black.

Cracking of the edges of a business card sometimes occurs when the card contains high values of ink, as in dark colors.

CLOSE UP OF BUSINESS CARD

This usually happens on a small amount of cards in the run. To prevent this, use lighter colors or if you must use dark colors, use as little ink as possible.

Many things can cause banding. Banding can be caused by the program that it is exported from, such as Indesign or Corel. Also, too many gradient steps, for example going from a very light color to a dark color, in a small area will cause banding.

CLOSE UP OF BANDING

To prevent this, check your digital files before sending. If you use a gradient, make sure it has enough room for a smooth transition.

When a job is coated with UV then scored and folded the job may begin to crack. During use, the cracks will become bigger and the ink may start to chip off.

CLOSE UP SCORING

Cracking is normal when coated jobs are scored and folded. Ordering the job without UV will help but may not prevent this. As the job is used and folded more and more, cracking will eventually happen.

There are three different ways Pantone colors can affect the way your job prints. The first is by object effects, such as shadows or glows, on top of your Pantone colors. To avoid this, convert all your Pantone colors into CMYK before submitting your order.

The second way Pantone colors can affect your file is when you use transparent images. To fix this issue, convert all your Pantone colors into CMYK. If you need to have a Pantone color in your art, for example when doing a silver 877c job, you must create a clipping mask around the image so the white area will not show up. This must be done before submitting the order.

The last way Pantone colors can affect your order is the color conversion between a Pantone color and CMYK. All of our normal printing is done in CMYK unless you specifically order a Silver, MU, or Custom job. If you use Pantone colors in a job that will print CMYK, your job might print with undesirable colors. If you send in a job with Pantone colors, the CMYK conversion will change the Pantone color. Before sending your order, make sure all Pantone colors have been converted to CMYK.

ESR quantities start from 25-250 and are printed on brand new, high tech digital equipment.

Our brand new Digital color presses are in a different class. The print quality of digital prints exceed professional standards. Here are a few facts about Digital Color Printing:

- Tests show digital quality matches offset.

- Digital printing offers larger color gamut.

- Print buyers find digital quality interchangeable with offset quality.

- Today, many showcase applications are printed digitally.

- Digital printing is more affordable for short runs, due to very low set up cost.

*disclaimer: Occasionally, quantities of up to 5000 and more might be printed using digital color technology in order to meet turnaround deadlines

When creating a Spot AQ job, you must include a Spot AQ template along with the regular full color file. The Spot AQ template file is used to show where the AQ will be placed.

NORMAL CMYK PRINT FILE SPOT AQ TEMPLATE FILE

Use white, 0C 0M 0Y 0K, to indicate where you would like the AQ. Black, 100%K, will indicate no AQ.

The USPS Every Door Direct Mail (EDDM) Program allows you to market by mail to households and businesses in targeted neighborhoods. Because the program is delivered to every door on a particular mail carrier's route the mailpieces do not require addresses or individual names. This also allows for a reduced postage rate. EDDM Retail is specifically designed for small volume mailers who mail less than 5,000 EDDM mailpieces a day and has special rules. For full details, please visit the USPS website Here, or visit our EDDM Section Here.

There’s both a minimum and a daily maximum. You must mail at least 200 pieces and to at least one carrier route each time you mail, so the minimum number of pieces required is the number of active deliveries on a single carrier route, but not less than 200. The maximum number of pieces is 5,000 per Post Office, per day. There’s also a limit of five 5-Digit ZIP Codes per EDDM Retail mailing.

No USPS postage permits or annual fees are required with EDDM Retail, but program registration with USPS is required (FREE). To begin the registration process through Clash Graphics, click here or contact us at info@clashgraphics.com.

EDDM Retail uses a “simplified” address of Postal Customer instead of street numbers or boxes so no mailing list is required. You just need a list of mail routes and active delivery counts, which can be obtained free of charge from the USPS EDDM website. Your target area can be a city, neighborhood or a specified distance from your business. To identify which USPS mail routes match your target area visit this USPS site for information about delivery routes and number of deliveries per carrier route.

Flats may be up from 6.25”x11” up to 12”x15” and can weigh up to 3.3oz. This is generally referred to as a flat. Most “flat” mailings used with EDDM are single sheet pieces printed on both sides within the dimensions listed above. For a list of the sizes we at Clash Graphics recommend for the most effective mailing campaign, click here.