You may also send the file in the following types: pdf, jpg, jpeg, psd, tif, tiff, eps, ai, and png

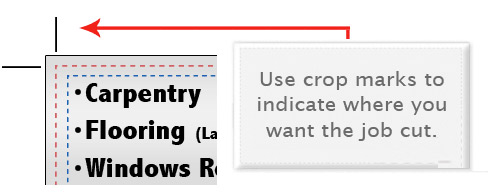

We prefer that you send .PDF and .EPS files with outlined fonts. These files are easier to handle and will likely speed up your turn-around. Remember to add crop marks and flatten your files before uploading.

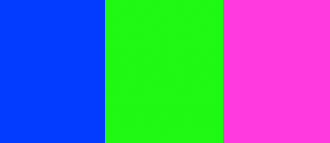

If you send us an RGB file, there is a chance that a color shift may occur and you may not be satisfied with your job.

THESE COLORS ARE IN RGB

THESE ARE THE SAME COLORS BUT IN CMYK

You should always start and finish your designs in CMYK color mode.

Low resolution files may be printed as is or will be placed on hold until we receive new files, slowing your turn-around.

THESE ARE 72 DPI LOW RES IMAGES

THESE ARE THE SAME IMAGES BUT AT 300 DPI

We only accept 300 dpi files and no less.

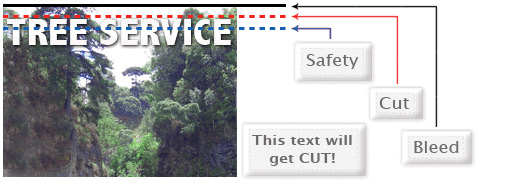

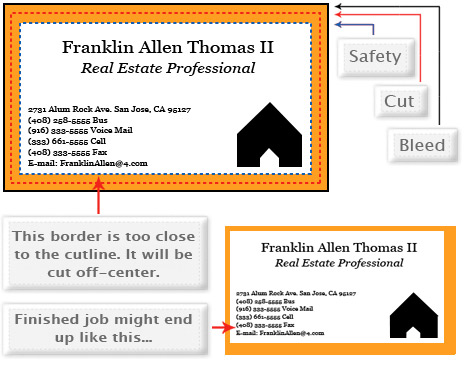

Bleed must extend further than the cut line. Using one of our Templates can help you visulize this. Please keep all text and anything you do not want to get cut off at least .125" away from the cut lines.

When sending an .eps or .pdf, make sure you include crop marks so we can cut the job correctly.

Click here to go to our production templates.

Yes but if the border is too close to the cutline, it may be off-center slightly.

We cut through many sheets at one time, so watch your borders to avoid an unwanted mistake.

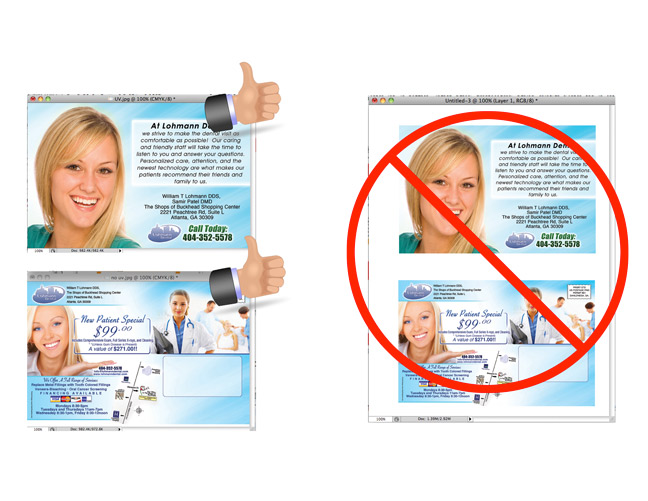

No. Each side of the job needs to be on a seperate file.

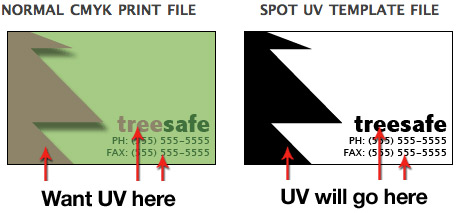

When creating a Spot UV Job, you must include a Spot UV template file along with the regular full color file. The Spot UV fileis used to show where the UV will be placed.

Use 100% K to indicate where you would like the UV. White will indicate no UV.

Silver ink files must be sent in a vector format. You must use a vector program, like Illustrator or Indesign, to call out the object you want in silver ink.

To indicate the silver ink, you must set the object color to Pantone¨ 877 C. Any other color will not be accepted as silver. Also, labeling the layer as "silver mask" or "silver" will not qualify your file.

VECTOR BASED PROGRAMS RASTER PROGRAMS

When using a blue in your design, always make sure to leave at least a 30% difference in your Cyan and Magenta values.

100% C 100% M 0% Y 0% K

ON SCREEN

AFTER PRINTING

Blue is close to purple in the CMYK spectrum. Remember, use a low amount of magenta whenever using high amounts of cyan to avoid purple.

EXAMPLE: C-100 M-70 Y-0 K-0

When exporting from any program such as Indesign or Illustrator, use these settings to make sure your .PDF files export correctly.

EXPORT SETTINGS FOR .PDF FILES

Adobe PDF Preset is set to: Press Quality

![]()

Compatibility is set to: Acrobat 4 (PDF 1.3)

![]()

Compress Text and Line Art is set to: Off

![]()

Grayscale images that are converted to CMYK will have a color shift in the final print. That shift may be green or yellow.

GRAYSCALE ON SCREEN

GRAYSCALE AFTER PRINT

Always check the CMYK values of your grayscale in the final CMYK document. If there are other values other than K in your grayscale image, there is a chance that the color will vary.

To eliminate all values other than K, use your Channel Mixer (adjustment layer) in Photoshop, then click "Monochrome" and adjust accordingly.

Rich black is an ink mixture of solid black, 100% K, with additional CMY ink values. This results in a darker tone than black ink alone. If you print black alone as 100% K, the resulting black may not be as dark as you might like.

100% K ON SCREEN

100% K AFTER PRINT

We recommend using C 60 M 40 Y 40 K 100

This will give you a deep, dark, rich black.

Cracking of the edges of a business card sometimes occurs when the card contains high values of ink, as in dark colors.

CLOSE UP OF BUSINESS CARD

This usually happens on a small amount of cards in the run. To prevent this, use lighter colors or if you must use dark colors, use as little ink as possible.

Many things can cause banding. Banding can be caused by the program that it is exported from, such as Indesign or Corel. Also, too many gradient steps, for example going from a very light color to a dark color, in a small area will cause banding.

CLOSE UP OF BANDING

To prevent this, check your digital files before sending. If you use a gradient, make sure it has enough room for a smooth transition.

When a job is coated with UV then scored and folded the job may begin to crack. During use, the cracks will become bigger and the ink may start to chip off.

CLOSE UP SCORING

Cracking is normal when coated jobs are scored and folded. Ordering the job without UV will help but may not prevent this. As the job is used and folded more and more, cracking will eventually happen.

There are three different ways Pantone colors can affect the way your job prints. The first is by object effects, such as shadows or glows, on top of your Pantone colors. To avoid this, convert all your Pantone colors into CMYK before submitting your order.

The second way Pantone colors can affect your file is when you use transparent images. To fix this issue, convert all your Pantone colors into CMYK. If you need to have a Pantone color in your art, for example when doing a silver 877c job, you must create a clipping mask around the image so the white area will not show up. This must be done before submitting the order.

The last way Pantone colors can affect your order is the color conversion between a Pantone color and CMYK. All of our normal printing is done in CMYK unless you specifically order a Silver, MU, or Custom job. If you use Pantone colors in a job that will print CMYK, your job might print with undesirable colors. If you send in a job with Pantone colors, the CMYK conversion will change the Pantone color. Before sending your order, make sure all Pantone colors have been converted to CMYK.

ESR quantities start from 25-250 and are printed on brand new, high tech digital equipment.

Our brand new Digital color presses are in a different class. The print quality of digital prints exceed professional standards. Here are a few facts about Digital Color Printing:

- Tests show digital quality matches offset.

- Digital printing offers larger color gamut.

- Print buyers find digital quality interchangeable with offset quality.

- Today, many showcase applications are printed digitally.

- Digital printing is more affordable for short runs, due to very low set up cost.

*disclaimer: Occasionally, quantities of up to 5000 and more might be printed using digital color technology in order to meet turnaround deadlines

When creating a Spot AQ job, you must include a Spot AQ template along with the regular full color file. The Spot AQ template file is used to show where the AQ will be placed.

NORMAL CMYK PRINT FILE SPOT AQ TEMPLATE FILE

Use white, 0C 0M 0Y 0K, to indicate where you would like the AQ. Black, 100%K, will indicate no AQ.

26.

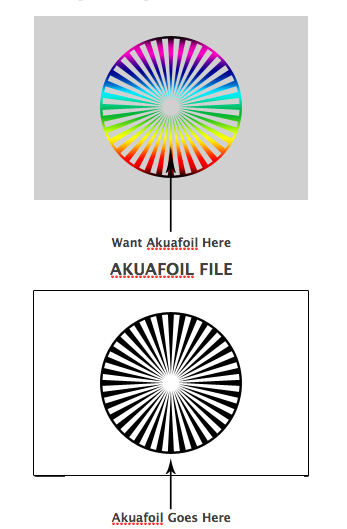

With Akuafoil, you can turn a wide range of CMYK colors, into multi-colored foils. Akuafoil uses a special processed foil system that is applied under 4/c process to create an array of foil colors. It's simple, affordable, and makes your prints stand out from the crowd.

For an Akuafoil job, you must include an Akuafoil/mask file along with your CMYK file. The mask file indicates where the foil will be placed. The file process is the same as spot UV—100% K where foil is placed, 0% where the foil is not placed.

NORMAL CMYK PRINT FILE

As shown above, the file on the left is the normal CMYK print file. If you want the logo to be Akuafoil, then your Akuafoil mask file should look like the file on the right. The White indicates no foil and 100% K indicates where the Akuafoil will be.

Here are some more things to keep in mind when creating your Akuafoil artwork:

- - Make sure the mask and CMYK print file are aligned and match up properly.

- - Akuafoil works best on lighter colors. The darker the CMYK color, the less the Akuafoil look.

- - Do not use very thin or small text and artwork with Akuafoil... Use san serif fonts above 12 point for best results.

If you would like only silver Akuafoil to print, make sure to have at least 15% K in that white area. White in the CMYK file that is 100% K in the Akuafoil file will appear as plain silver Akuafoil. However, for a higher quality plain silver Akuafoil, we recommend to have at least 15% K in that white area.

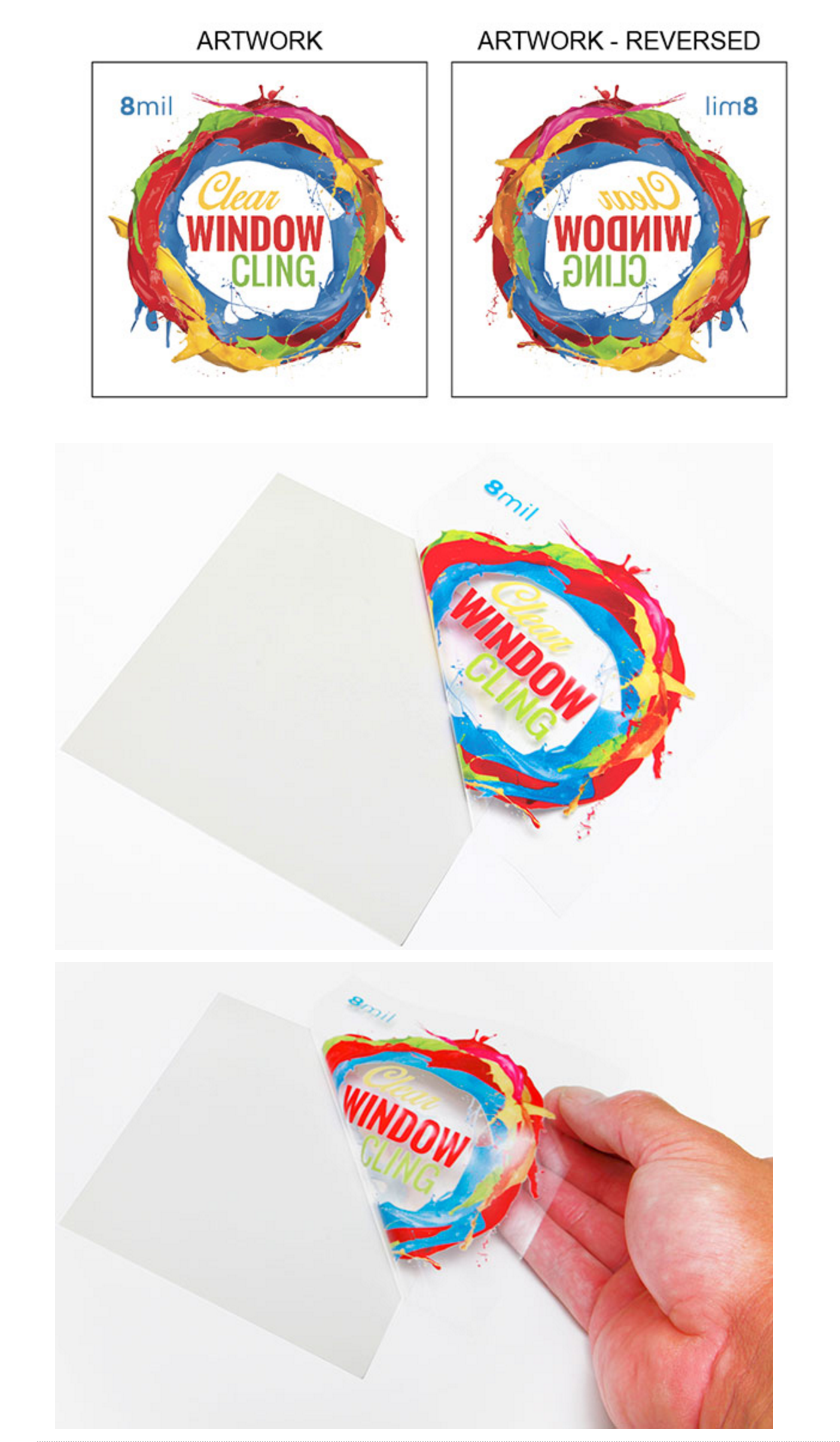

27. WINDOW CLING

Window Clings are printed at near photo quality on glossy material suitable for indoor or outdoor use. Ideal for POP signage on glass or other very smooth, clean surfaces. Window Clings should be applied on a surface that is as close to room temperature as possible. Excessive heat or cold will not allow the product to cling to the surface. The product is shipped rolled for most sizes unless ordering larger quantities.

White Window Clings are 7mil thick with a paper backer that will be peeled off prior to application. Material will only cling on the back side of the print.

Clear Window Clings are 8mil thick with a paper backer that will be peeled off prior to application. Material will only cling on the front side of the print. White ink is available as an overprint option for added opacity and vibrant color.

Bleed: ensure you have .25" on all sides of your artwork, do not add crops